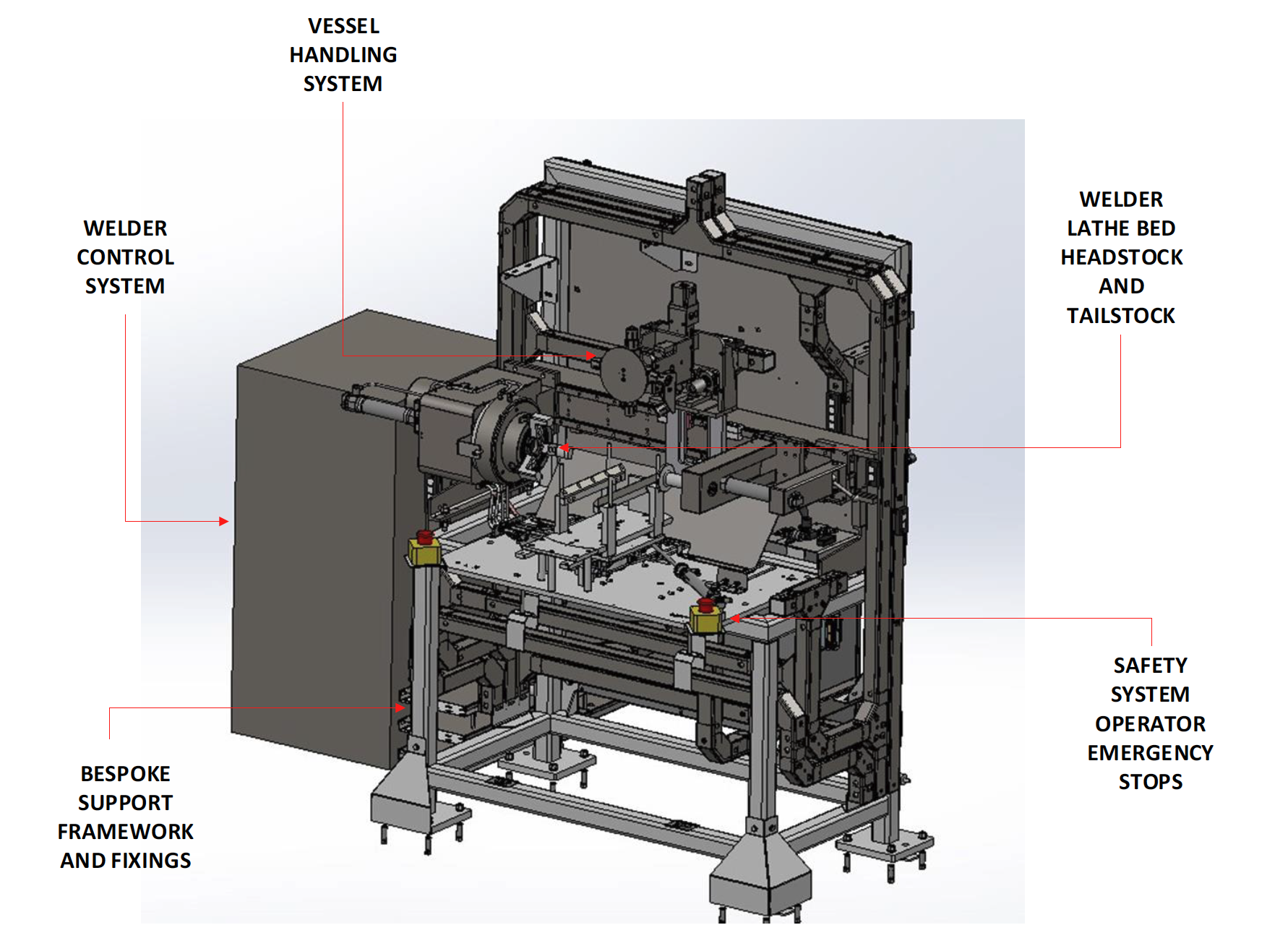

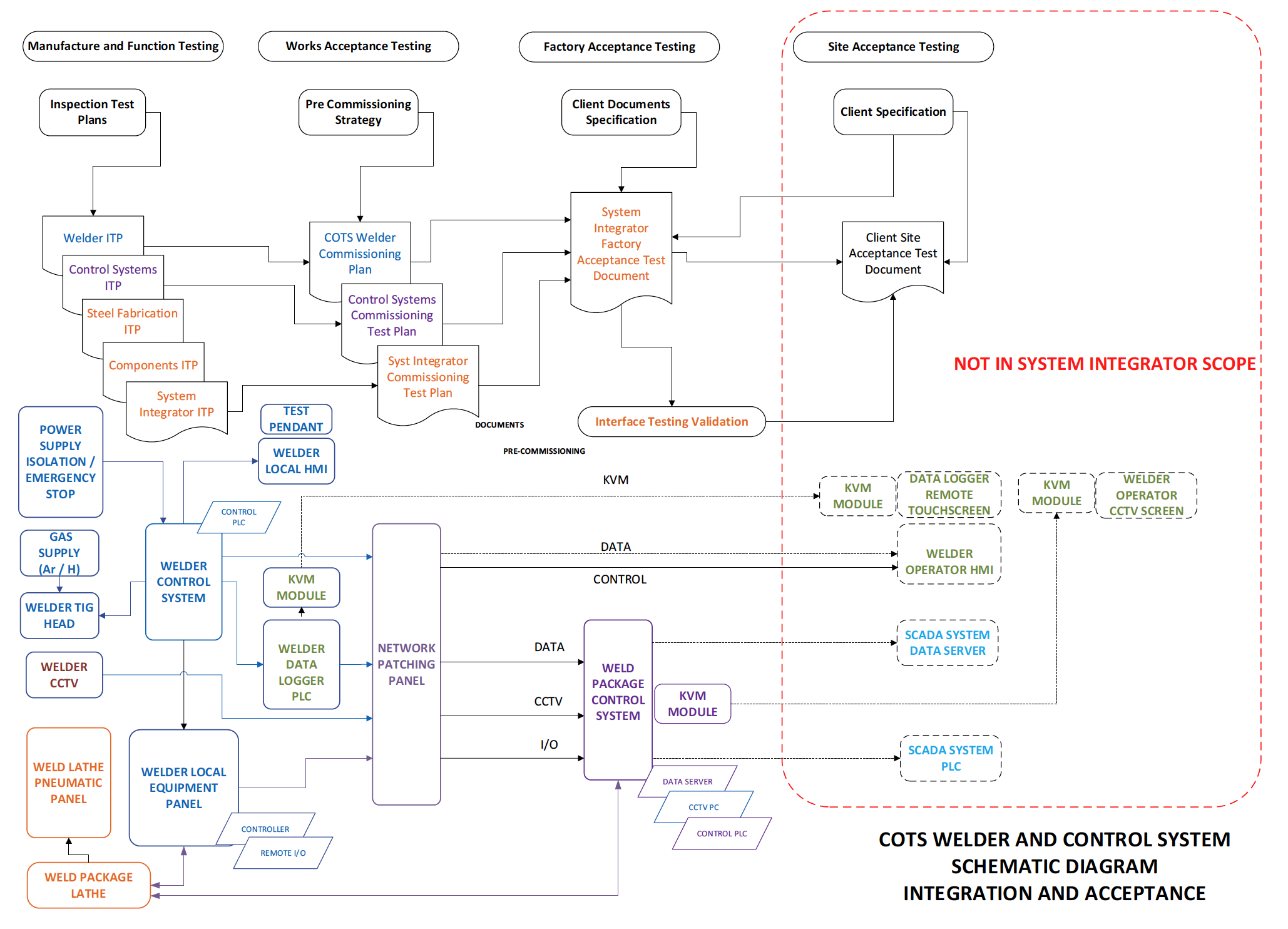

COTS TIG Welder System

Integration within bespoke vessel handling and control system

Overarching SCADA system

Data and CCTV capture Systems

COTS Welder and Control System

Task:

System Architecture and Configuration for installation in a dedicated workshop assumptions

- 415 Volts AC Supply, 200 Amps DC Welder

- Rotating Lathe Bed Headstock < 10RPM electric motor

- Pneumatic Actuation Chuck and Tailstock < 10 Bar Compressed air

- Vessel Handling System < 50 kg load

- Welding Gas Argon >95% and Hydrogen <4%

- Weld Control System Allen Bradley Industrial PLC, COTS I/O and Comms

- Vessel Control System PLC Allen Bradley Industrial PLC and Proprietary I/O Comms

- SCADA System Comms Ethernet (TCP/IP) with cyber security hardening.

- What documents would you expect to see or produce to validate the suppliers COTS equipment and integration into the overall Control and Monitoring Systems at the Design Stage.

- What approaches or Strategies could be used to validate the performance and verify the design intent post equipment Specification.

- What standards apply for the equipment architecture and system parameters shown

- What safety requirements are relevant to this equipment and how would these be identified and substantiated

- Explain the system high failure modes and what mitigations you would consider to ensure a safe by design solution