Project details

Aims and Objectives

Magnox engaged Aquila Nuclear Engineering Ltd to design, manufacture and deliver a Drum Housing Unit for radon monitoring.

About the client

Magnox Ltd is the management and operations contractor responsible for safely managing 12 nuclear sites and one hydroelectric plant in the UK, working for the sites’ owner, the Nuclear Decommissioning Authority (NDA).

Magnox is responsible for managing the sites through their lifecycles, overseeing all aspects of defuelling and decommissioning.

Project Overview

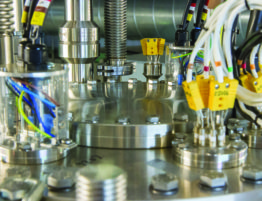

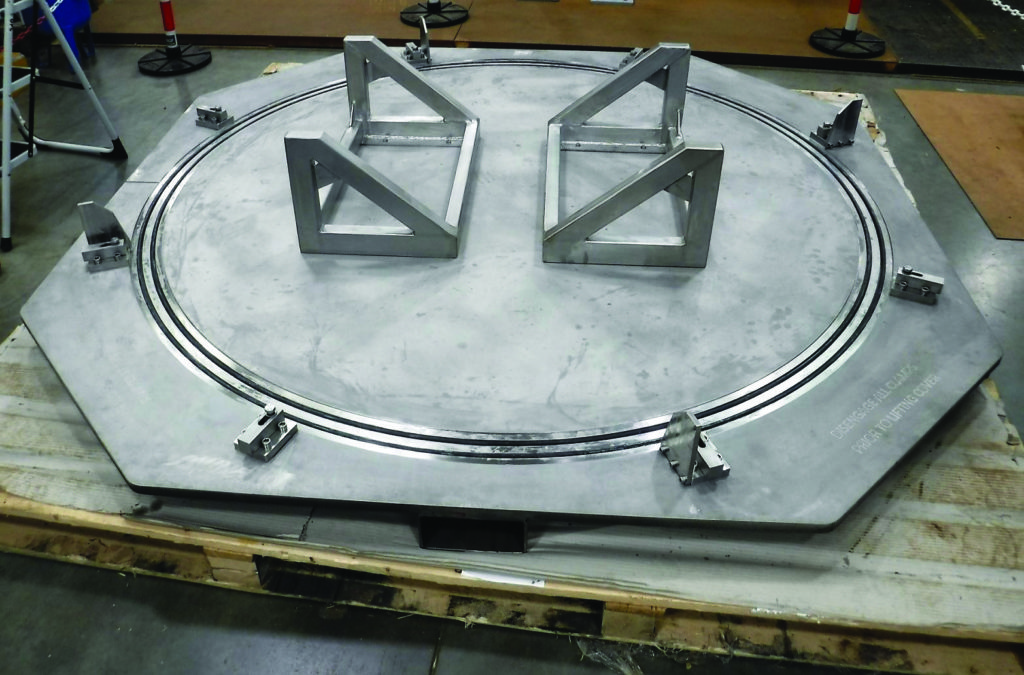

The Drum Housing Unit (DHU) comprises a base plate, on which the drums were placed, and a removable cover. Once assembled, the cover provided a gas-tight containment for the drum on the base plate. The design included a double seal between the base plate and the cover to prevent radon gas from leaking out of the DHU during radon gas measurement.

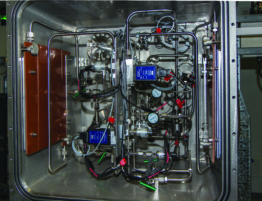

Radon gas measurement is carried out by an AlphaGUARD radon monitoring device. If radon gas is detected after the measurements have been completed, the containment space is vented using an industrial vacuum. Penetrations for testing and venting were incorporated into the cover.

Full Specification

Radon gas monitoring is performed using an AlphaGUARD, supplied by Magnox. The AlphaGUARD has a dedicated housing on the cover assembly providing some protection from the external environment. The monitoring process is owned by Magnox.

The cover is a fabricated assembly with 4 x lifting eyes for lifting the cover assembly. The cover includes process connections for pipework to operate the AlphaGUARD equipment and 2 x ball valves to allow connection of a vacuum cleaner, supplied by Magnox for removal of radon gas. 2 x blanking plugs are also included to allow for termination of valve outlets when not in use, and the lower flange sealing face includes a tapping point for pressure testing.

To prevent damage when removed from the base plate, the cover is stored on a dedicated stand. This prevents the cover resting on the sealing face which could lead to damage and subsequent leaking of radon gas.

The base plate is a fabricated assembly with 2 x O-ring seals which interface with the cover plate sealing flange. Fork lift pockets allow the DHU assembly (base plate and cover) to be lifted as a single unit. 8 x clamp bars are employed to secure the cover plate and compress the O-ring seal. To aid installation of the cover plate 4 x guide plates have been incorporated into the design. 2 x removable drum supports were included in the scope so that drums can be loaded vertically or horizontally.