Project details

Category: Containment

Status: Complete

Client: University of Southampton (NNUF-EXACT Facility)

For more information:

Aims and Objectives

The glovebox is housed in the NNUF-EXACT facility at the National Oceanography Centre in Southampton. The National Nuclear User Facility (NNUF) is a distributed centre of excellence in nuclear science and technology.

The facility required enhanced ‘in-house’ capability for the handling of radioactive or chemically hazardous materials. A glovebox system represented best practice in terms of reducing the likelihood of operator exposure, thus keeping exposures as low as reasonably practicable (ALARP).

Project Overview

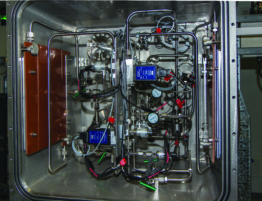

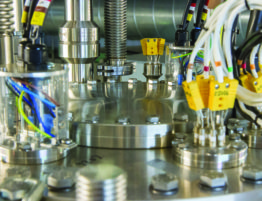

Cyclife Aquila Nuclear (CAN) was awarded the contract for the design, build, delivery, installation, commissioning and training of the glovebox. For this project CAN collaborated with Cirrus Containments who provide high quality, modular isolation units, that can be customised for the needs of hospitals, pharmacies and academic institutes.

The glovebox extends the range of materials that can be safely handled by the facility whilst ensuring the safety of staff / students and compliance with the ALARP principle.

NNUF-EXACT specified a number of requirements to achieve compliance including a custom ‘push through’ HEPA filter system which allowed their technicians to replace the filter and ‘bag out’ the used filter without breaking containment.

The glovebox delivered met all requirements and included:

- EC GMP Grade A Turbulent Airflow

- ISO 10648-2 Class 2 Leak Tightness

- Negative Pressure (-250 to -500 Pa)

- 3mm Thick Bead Blasted 316L Stainless Steel Enclosure

- 12mm Clear Acrylic Window with bonded ø250mm Glove Ports

- 400 x 400 x 600mm Antechamber, Fully Interlocked

- EU14 HEPA Filtering

- Fully Automatic Leak Test

- UPS Battery Backup

- Ventilation Monitoring and Failure Alarm

During the execution of the project a number of further requirements were identified resulting in additional equipment being designed, built and supplied, including:

- Air Bleed Valve Assembly (for interfacing with the Building HVAC)

- Secondary Filter System (additional protection against contamination entering the Building HVAC)

- Internal Tooling Plate and Rail System (for ergonomic handling of materials within the glovebox)

Summary

The synergy of CAN’s nuclear containment heritage and Cirrus’ knowledge of radiopharmaceutical isolators made for a strong partnership in delivering the specification requirements to the NNUF-EXACT facility.

CAN’s ‘light touch’ with the project meant that NNUF-EXACT received the most cost effective offering we could provide to meet their requirements.

A close, collaborative work relationship between the three parties ensured the project was delivered on time and on budget.

To find out more about our gloveboxes and containment capability, click here: Containment – Cyclife Aquila Nuclear | EDF Group