Project details

Category: Remote Handling

Client: Mirion Technologies

Status: Complete

For more information:

Aims and objectives

Aquila was awarded the contract to manufacture a Passive/Active Neutron Monitor (PANM) system, as part of the Electro Mechanical package, working with Mirion’s measurement chains and software systems.

About the client

Mirion Technologies is a leading provider of innovative products, systems and services related to the measurement, detection, and monitoring of radiation. In close partnership with its customers, Mirion strives to deliver cutting edge products and services worldwide.

Project Overview

Aquila was awarded the contract to manufacture a Passive/Active Neutron Monitor (PANM) system, as part of the Electro Mechanical package, working to Mirion’s measurement chains and software systems.

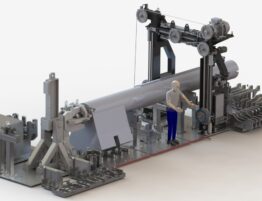

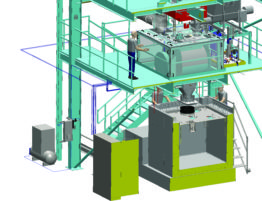

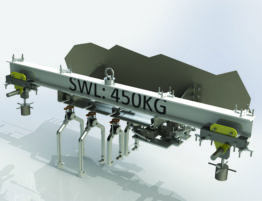

The PANM was installed within a fully remotely operated facility, using manipulators and cranes. The system design incorporated instrumentation for waste assessment and classification of drums during decommissioning operations. The design uses highly accurate neutron measurement techniques, gamma measuring systems and mass measurements to assay individual drums.

The skid assembly is the base support structure that the PANM is built upon. The structure has been designed to pass all the static and dynamic loads of the PANM, including predesignated steel pads in the plant building. The system has been seismic qualified to KTA standards.

100mm-thick lead panels are used to protect the Neutron measuring equipment and the 140mm HDPE instrument shielding is used for the outer layer of the DMC and provides the Neutron shielding around the drum.

The main function of the Door Carriage Assembly is to transport the vertically loaded drum into the DMC drum and into the DMC, during the measurement process. Once the DMC is loaded and closed, the drum is rotated, and the measurement process commences.

In the event of any system failures, the drive mechanism can be decoupled remotely, allowing the Door Carriage Assembly to be withdrawn and the active drum removed, allowing access for maintenance.

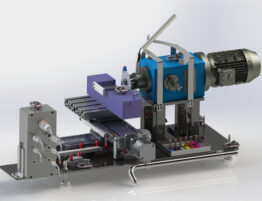

EC&I assembly provides power and control features for the PANM, which includes a Door Motion System, Gamma Detector Attenuation System, E-stop Safety Circuit and Fortress Interlock Key to determine the remote and local functions.

Summary

Aquila manufactured and installed the Passive Active Neutron Monitor to Mirion’s specification and is another great example of Aquila’s pragmatic and cost-effective design and approach.