Project details

Aims and Objectives

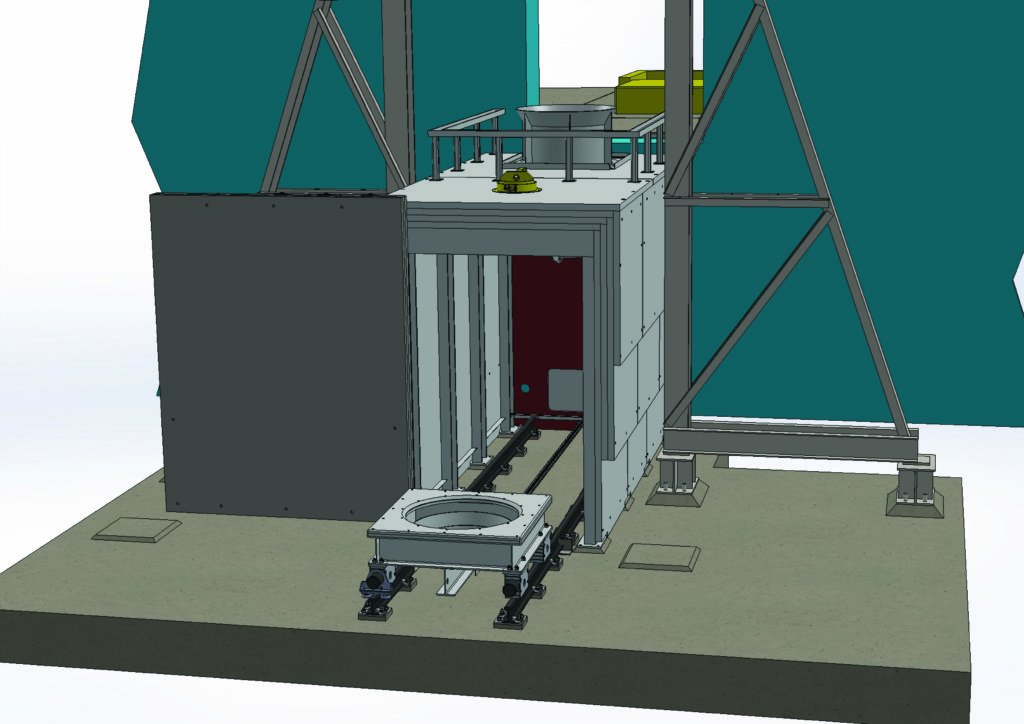

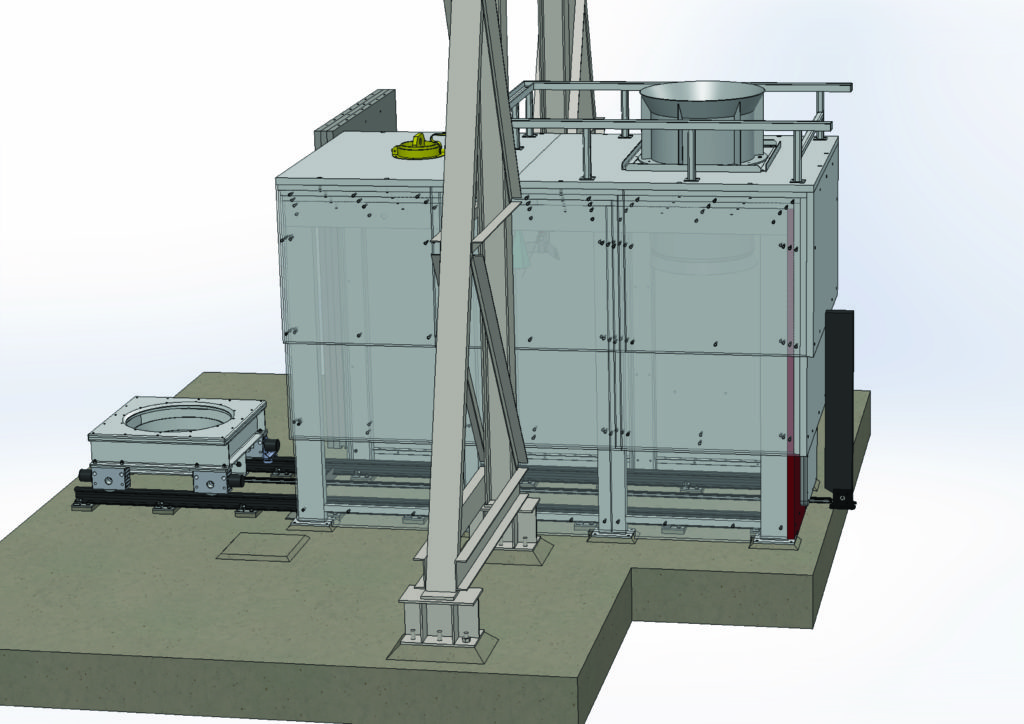

The project was to design, manufacture, factory test, install and commission two pieces of plant for the Chute Silo Project at Berkeley; a Shielded Transfer Flask & an Import/Export Facility. This case study describes the import/export facility.

About the client

Magnox Ltd is the management and operations contractor responsible for safely managing 12 nuclear sites and one hydroelectric plant in the UK, working for the sites’ owner, the Nuclear Decommissioning Authority (NDA).

Magnox is responsible for managing the sites through their lifecycles, overseeing all aspects of defuelling and decommissioning.

Project Overview

The Chute Silo ILW project, was set up by Magnox, to retrieve waste in the form of irradiated control rods and charge chutes, from a storage silo on the Berkeley nuclear site.

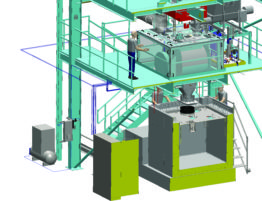

The project involved carrying out in-silo, size reduction of the waste, retrieval from the silo and transfer of the waste to a shielded container for export to an on-site storage facility.

A scheme design was produced for the process and equipment to carry Out the Chute Silo Project.

This equipment comprised:

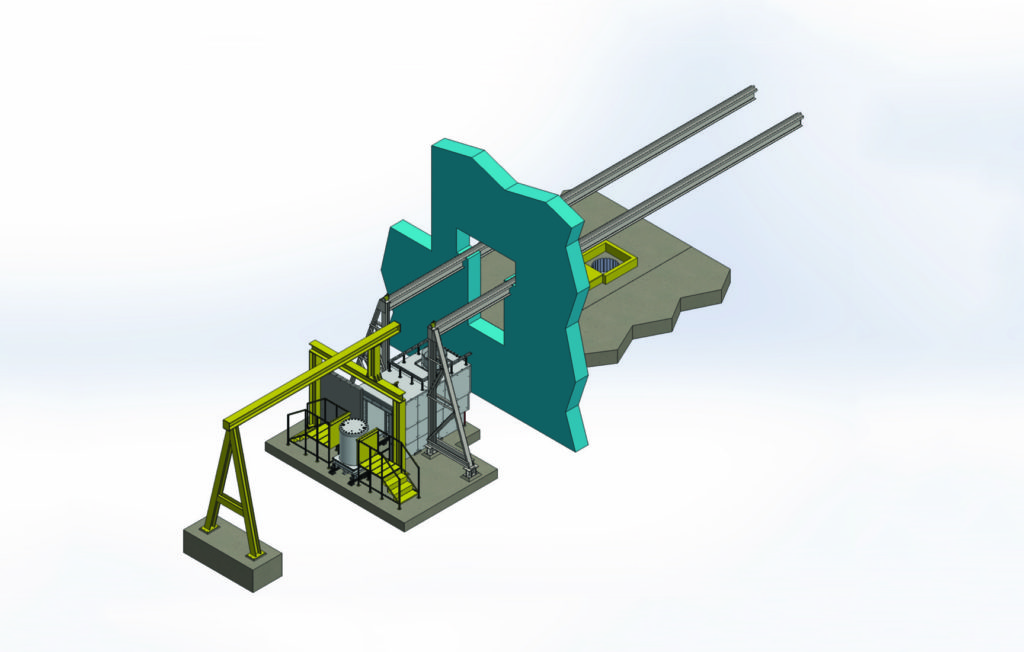

- Transfer Flask to transfer the waste retrieved from the silo to an external facility/module.

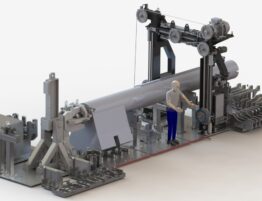

- Import/Export facility to receive waste packages from the Shielded Transfer Flask and facilitate the waste packages being loaded into Ductile Cast Iron Containers (DCIC).

Health and safety was the primary objective but during the design a high emphasis was placed on the duty and fit for purpose since it was estimated that only 35 transfers were required between the chute silo and the import/export facility.

Summary

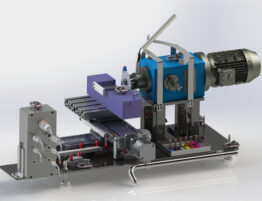

During the tender process, Aquila designed a system in 3D solid works to meet the functional specification. This not only allowed us to de-risk the design from a functional aspect but also enabled accurate estimating to fix the price.