Project details

Category: Shielded Facilities

Status: Complete

Client: Cavendish Nuclear

For more information:

Aims and Objectives

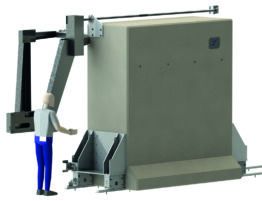

Aquila Nuclear Engineering designed and supplied the equipment and services required for pre-conditioning sludge wastes. The design receives and dewaters the sludge which will then be transferred to an external mixer and poured into a concrete box.

About the client

Cavendish Nuclear offers experience and specialist knowledge across all aspects of the nuclear energy life cycle, from design and build, through operations and maintenance, to decommission, waste management and remediation.

Project Overview

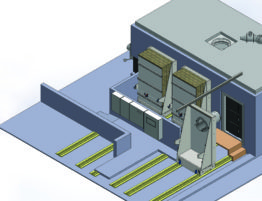

The Pre-Conditioning Facility (PCF) at Hinkley Point “A” (HPA) shall pre-condition mobile Intermediate Level Waste (ILW) following two pre-conditioning routes; polymer route generally for IX material wastes, and cement powder addition generally for sludge wastes.

The PCF is to process several waste streams at HPA. The design will receive and process sludge and supernatant from a number of different waste streams.

- The design broadly consists of the following components:

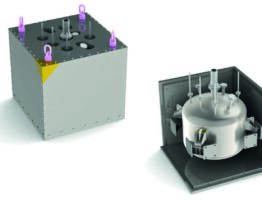

- Access and support structure including:

- 2 x 3000L settlement tanks

- Bunds

- 60mm shielding

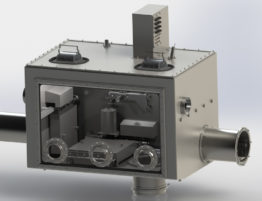

- Pumps, valves and pipework

- Excess Supernatant Storage Tank (ESST)

- Dosing skid

- Control system

Summary

Aquila has coupled a no-nonsense design approach with the use of standard components and conventional manufacturing materials and methods. This has resulted in a cost effective and fit for purpose solution.