Project details

Category: Remote Handling

Status: Complete

Client: National Nuclear Laboratory (NNL)

For more information:

Aims and Objectives

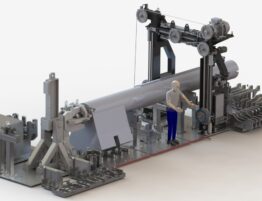

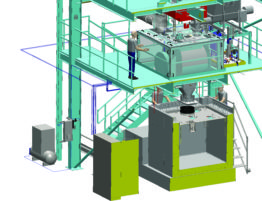

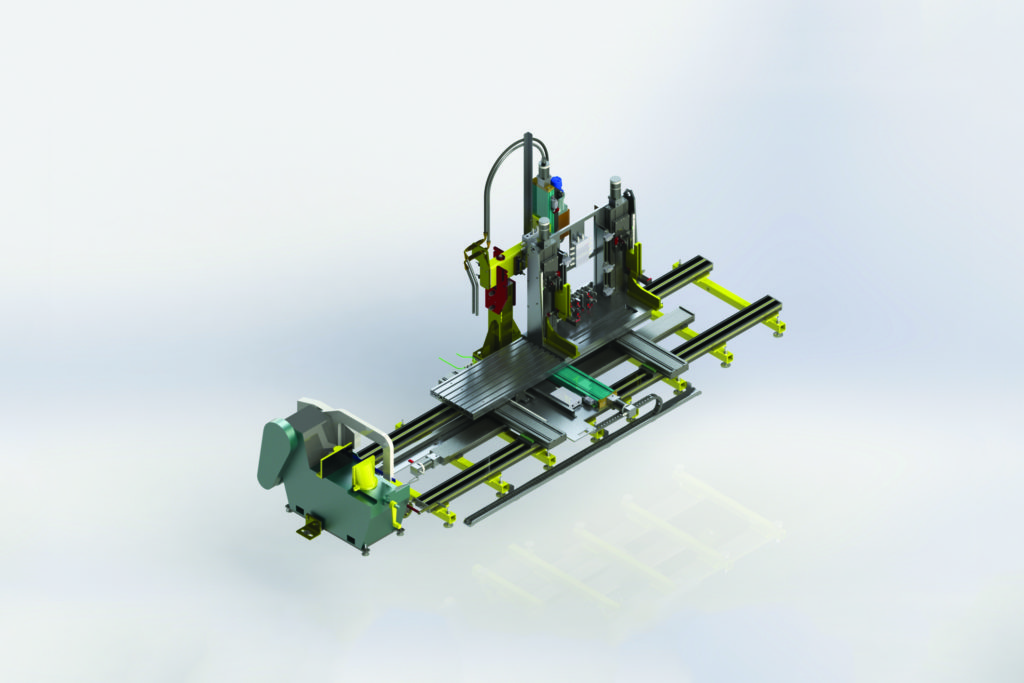

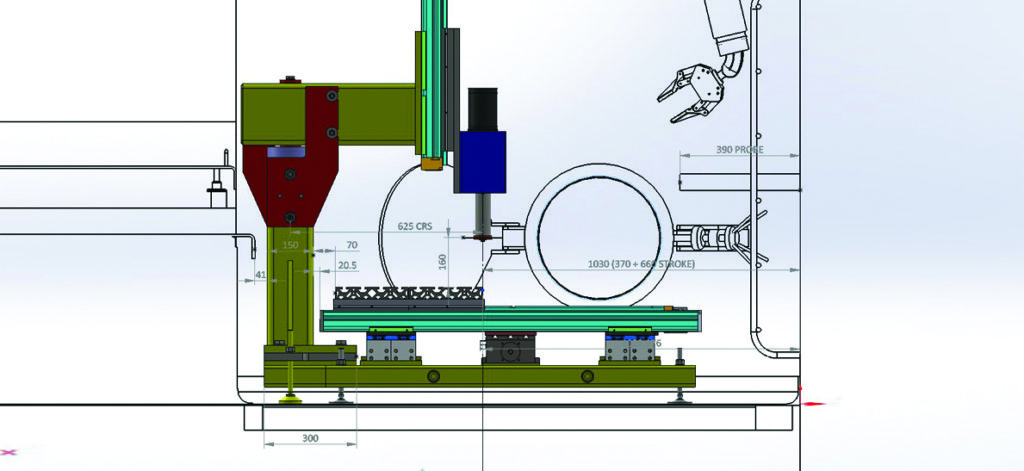

The functional objective for NNL was to provide equipment which could remotely dismantle irradiated components for mechanical and chemical evaluation. The project objective for Aquila was to design, manufacture and works test a remotely operated XY table together with an integrated radial arm drill winching system and cutting equipment. The analysis and breakdown equipment is imported into the cave assembled, and operated and maintained remotely using an in cell cave crane and Master Slave Manipulators.

About the client

The National Nuclear Laboratory (NNL) operates a number of facilities offering research, development and consultancy services to the nuclear industry. At the Sellafield site, the NNL Windscale Laboratory operates a range of radiation shielded facilities where nuclear materials are processed and examined. Services include Post Irradiation Examination (PIE) of nuclear fuel and irradiated material, radioactive waste handling and material analysis and testing.

Project Overview

The equipment receives an irradiated component horizontally from a transport flask via a horizontal posting port. The component is then transferred onto a reception winch where a special lifting grab lifts the component onto the XY table. The equipment then dismantles the irradiated component remotely employing the radial arm drill, powered hacksaw and other specialist tooling. The irradiated components and sub components undergo further analysis within the cell cave.

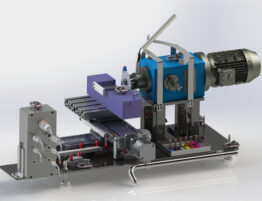

All drives employed are hydraulic motors within the cave. The XY table offers an accuracy of ±0.4mm feedback with a speed of 0-20mm/second. The powered hack saw offers a cut 225mm x 225mm cross section and the saw blades are capable of being replaced by a Master Slave Manipulator.

Summary

Aquila offered Commercially Off The Shelf (COTS) proprietary components wherever possible and allowed for proving trials within the offer to validate the design proposals. All factory acceptance testing was carried out within Aquila workshops.